CuraFloWT (Water Treatment System) – Decades of experience restoring failing plumbing systems in every type of building, commercial, residential and institutional, has provided the CuraFlo team an in-depth understanding of the mechanisms of pipe corrosion, how it plays out in a building’s plumbing system, and how and when pipe corrosion will leads to pipe failure. With that knowledge and the latest testing and inspection techniques the CuraFlo team and its associates, develops a profile of the existing corrosion in the building’s plumbing system and is able to predict how that corrosion will progress thought the system over time. Armed with this detailed understanding of your building’s plumbing system the CuraFlo Team is able to address the existing pipe failures (corrosion issues) in the building’s plumbing system, head-off future issues, then design and build a corrosion resistant system using Pipe Replacement, Pipe Lining, Water Treatment or a combination of the three methodologies.

While CuraFlo’s pipe lining and repipe services may be the best ways of building a durable plumbing system in some buildings, they may not always be the best fit for some buildings and their Owners. System design, building use, and budgets, may dictate the best approach for restoring a failing plumbing system. For some building Owners, repipe may prove too invasive a procedure, while another building’s existing plumbing system may no longer match future use of the space necessitating a complete system re-design. Yet another building may find that lining the existing system while upgrading a few valves and fittings, may fit the bill perfectly, reducing overall costs and the intrusiveness of the work. CuraPoxy’s inherent resistance to chlorine attack makes it more durable than plastic pipes, that commonly relies on additives to their formulations for the product to have a long life despite exposure to aggressive / highly chlorinated water conditions (https://plasticpipe.org/pdf/tn-53-pex-chlorine-ratings.pdf), while Cuapoxy does not require any additives to its formulation to remain resistant to chlorine.

While CuraFlo’s pipe lining and repipe services may be the best ways of building a durable plumbing system in some buildings, they may not always be the best fit for some buildings and their Owners. System design, building use, and budgets, may dictate the best approach for restoring a failing plumbing system. For some building Owners, repipe may prove too invasive a procedure, while another building’s existing plumbing system may no longer match future use of the space necessitating a complete system re-design. Yet another building may find that lining the existing system while upgrading a few valves and fittings, may fit the bill perfectly, reducing overall costs and the intrusiveness of the work. CuraPoxy’s inherent resistance to chlorine attack makes it more durable than plastic pipes, that commonly relies on additives to their formulations for the product to have a long life despite exposure to aggressive / highly chlorinated water conditions (https://plasticpipe.org/pdf/tn-53-pex-chlorine-ratings.pdf), while Cuapoxy does not require any additives to its formulation to remain resistant to chlorine.

For many buildings The CuraFloWT (Water Treatment System) with its cost effective / non-invasive approach to plumbing system renewal will prove the perfect and most cost-effective solution for addressing the building Owners plumbing troubles.

Understanding pipe corrosion and how to prevent it:

Corrosion in drinking water distribution systems can be caused by several factors, including the type of materials used, the quality of the workmanship along with how well flushed the system was on initial start-up, the age of the pipes and fittings, the stagnation time of the water and the water quality in the system, including its pH as well as the water’s hard/soft classification and residual chlorine levels. It should be noted the pipe corrosion also contributes to degrading water quality.

According to National Association of Corrosion Engineers (NACE) Public utilities spend $36 Billion per a year in the USA addressing pipe corrosion issues.

While in Canada the Federal Government committed an extra $800,000,000.00 in 2017 to 603 projects to ensure clean water for Canadians. (http://publications.gc.ca/site/archivee-archived.html?url=http://publications.gc.ca/collections/collection_2017/infc/T91-4-2017-eng.pdf)

While utilities spend vast amounts of money on corrosion control in an effort to improve water quality it has never proven sufficient to protect the end users from pipe failure and contaminates leaching in to their water supply and further contributing to premature pipe failures. The water delivered to many buildings in North America is still very aggressive, plumbing system corrosion continues, while leaching of lead and other metals in to the domestic water systems is a growing problem and pipe failures are occurring more frequently than ever.

Understanding pipe corrosion and how to prevent it:

Corrosion in drinking water distribution systems can be caused by several factors, including the type of materials used, the quality of the workmanship along with how well flushed the system was on initial start-up, the age of the pipes and fittings, the stagnation time of the water and the water quality in the system, including its pH as well as the water’s hard/soft classification and residual chlorine levels. It should be noted the pipe corrosion also contributes to degrading water quality.

According to National Association of Corrosion Engineers (NACE) Public utilities spend $36 Billion per a year in the USA addressing pipe corrosion issues. (https://www.nace.org/uploadedFiles/Publications/ccsupp.pdf )

While in Canada the Federal Government committed an extra $800,000,000.00 in 2017 to 603 projects to ensure clean water for Canadians. (http://publications.gc.ca/site/archivee-archived.html?url=http://publications.gc.ca/collections/collection_2017/infc/T91-4-2017-eng.pdf)

While utilities spend vast amounts of money on corrosion control in an effort to improve water quality it has never proven sufficient to protect the end users from pipe failure and contaminates leaching in to their water supply and further contributing to premature pipe failures. The water delivered to many buildings in North America is still very aggressive, plumbing system corrosion continues, while leaching of lead and other metals in to the domestic water systems is a growing problem and pipe failures are occurring more frequently than ever.

Understanding pipe corrosion and how to prevent it:

Corrosion in drinking water distribution systems can be caused by several factors, including the type of materials used, the quality of the workmanship along with how well flushed the system was on initial start-up, the age of the pipes and fittings, the stagnation time of the water and the water quality in the system, including its pH as well as the water’s hard/soft classification and residual chlorine levels. It should be noted the pipe corrosion also contributes to degrading water quality.

According to National Association of Corrosion Engineers (NACE) Public utilities spend $36 Billion per a year in the USA addressing pipe corrosion issues. (https://www.nace.org/uploadedFiles/Publications/ccsupp.pdf )

While in Canada the Federal Government committed an extra $800,000,000.00 in 2017 to 603 projects to ensure clean water for Canadians. (http://publications.gc.ca/site/archivee-archived.html?url=http://publications.gc.ca/collections/collection_2017/infc/T91-4-2017-eng.pdf)

While utilities spend vast amounts of money on corrosion control in an effort to improve water quality it has never proven sufficient to protect the end users from pipe failure and contaminates leaching in to their water supply and further contributing to premature pipe failures. The water delivered to many buildings in North America is still very aggressive, plumbing system corrosion continues, while leaching of lead and other metals in to the domestic water systems is a growing problem and pipe failures are occurring more frequently than ever.

How the CuraFloWT (Water Treatment System) combined with targeted pipe upgrades – a cost effective solution to your pipe troubles.

The CuraFloWT (Water Treatment System) slows down and even stops the mechanisms of pipe corrosion while significantly reducing the leaching of metals and other materials into a buildings domestic water supply from the plumbing system. To be clear unlike pipe replacement and epoxy lining, water treatment will not remedy years of  pitting and other forms of corrosion that has occurred from normal use since the system was put into service. It will significantly slow down the progression of the corrosion and leaching extending the service life of the pipes by many years. Pipes in a building do not all fail at the same time. The progression of pipe corrosion is different in each plumbing system, section to section as well as with different types of water conditions. Soft / hot water pitting corrosion is the most common and tends to progress most quickly in the hot mains and the hot water recirculation lines, but each building and water chemistry poses its own unique corrosion/pipe failure issues. By running a variety of inspections and tests on a building’s plumbing system it is possible to identify the pipes in a building with the most advanced corrosion, so that these can be targeted for upgrading. Some buildings may only be in the early stages plumbing system corrosion and CuraFloWT alone may be sufficient to ensure no more leaks, while other buildings may require upgrading of a few of the most heavily used (corroded) pipes. This combination of water treatment with pipe lining or replacement makes water treatment a far more effective solution to plumbing system failure than water treatment alone while keeping project costs and overall project intrusiveness under control.

pitting and other forms of corrosion that has occurred from normal use since the system was put into service. It will significantly slow down the progression of the corrosion and leaching extending the service life of the pipes by many years. Pipes in a building do not all fail at the same time. The progression of pipe corrosion is different in each plumbing system, section to section as well as with different types of water conditions. Soft / hot water pitting corrosion is the most common and tends to progress most quickly in the hot mains and the hot water recirculation lines, but each building and water chemistry poses its own unique corrosion/pipe failure issues. By running a variety of inspections and tests on a building’s plumbing system it is possible to identify the pipes in a building with the most advanced corrosion, so that these can be targeted for upgrading. Some buildings may only be in the early stages plumbing system corrosion and CuraFloWT alone may be sufficient to ensure no more leaks, while other buildings may require upgrading of a few of the most heavily used (corroded) pipes. This combination of water treatment with pipe lining or replacement makes water treatment a far more effective solution to plumbing system failure than water treatment alone while keeping project costs and overall project intrusiveness under control.

Benefits of Using CuraFloWT (Water Treatment System):

Reduce Soft Water Corrosion (Hard Water is less aggressive)

Balanced & PH Control

Keep Pipe Healthy Longer

Low Cost

Fast Results

Safe: Meets Local and National Regulatory Requirements

Controls Pinhole Leak Formation

24-7 Support

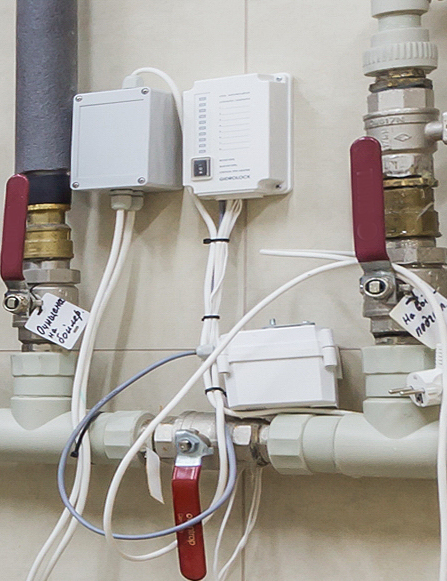

24-7 Remote Monitoring

No Expensive Contract Purchases

Water Treatment creates a safe Bio-film that protects the pipe’s interior surfaces from corrosion, while buffering the water (raising the pH) and moving the water chemistry a less aggressive chemistry (not too hard and not too soft).

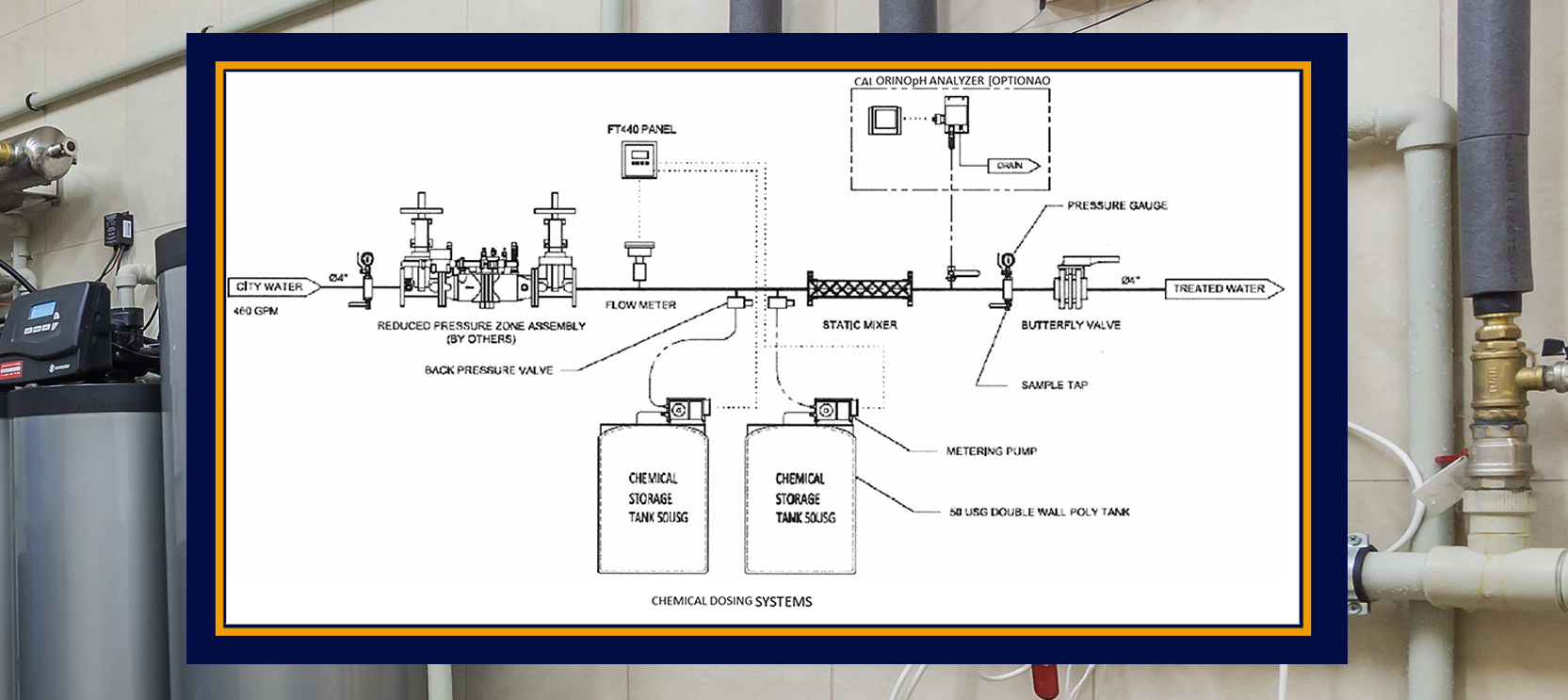

The CuraFlo Water Treatment System consists of a control system, metering / dosing pumps and onsite storage tanks for the water treatment supplies. Regular site visits for testing and system adjustments (and/or on-line monitoring) ensures that the dosing system is delivering the correct amount of the buffering agent (baking soda) to the buildings water supply as well as just the right amount of corrosion inhibiter (zinc orthophosphate), shutting down the mechanisms of corrosion.

Results vary from building to building, however, CuraFloWT usually offers quick results, slowing down and preventing further leaks. As stated, results vary from building to building, plumbing system to plumbing system, depending on how advanced the corrosion is at the time of installation.

A few factors that can affect how well Water Treatment will work in a particular building include:

- How Badly Corroded the Pipes are at the Time of Installing the Water Treatment System

- Plumbing System Design and Layout

- Materials Used to Construct the System

- Quality of Workmanship Applied to Original Construction

- Operating Temperature of the System

The CuraFlo team with their decades of experience with failing plumbing system can help with a comprehensive examination of the existing piping systems employing a wide very of tools to probe and inspect the system inside and out, detailing the levels of corrosion found inside and out of the hot, cold, and hot water re-circulation pipe systems. Once completed, projections can be made regarding expected results from a Water Treatment System being added to a building’s plumbing system. In addition to Water Treatment other adjustments to the water temperatures and flow rates may need to be made to some buildings plumbing systems to ensure water treatment is most effective.

For buildings, with more advanced pipe corrosion, targeting the most severely corroded pipes for replacement or epoxy lining prior to adding Water Treatment to the entire system maybe necessary, as this may help Water Treatment address the pipe problem more effectively while still keeping costs to a fraction of that of a full on repipe or lining project.

CuraFlo’s combination of a detailed examination of the existing pipes condition with “as required” targeted piping system upgrades of the most corroded pipes, followed by the installation of the CuraFloWT System to prevent further degradation of the pipes, elevates the Water Treatment approach to addressing leaking pipes issues to a higher level. The CuraFloWT system removes any uncertainty owners may have regarding just how effective Water Treatment will be at stopping pipe leaks for their building.

CuraFlo’s combination of a detailed examination of the existing pipes condition with “as required” targeted piping system upgrades of the most corroded pipes, followed by the installation of the CuraFloWT System to prevent further degradation of the pipes, elevates the Water Treatment approach to addressing leaking pipes issues to a higher level. The CuraFloWT system removes any uncertainty owners may have regarding just how effective Water Treatment will be at stopping pipe leaks for their building.

In addition to the above process, ask your CuraFlo representative for details on how it is that CuraFlo is the only Water Treatment company to not lock customers into long-term contracts.

Click below to see CuraFloWT (Water Treatment System) – Material Safety Data Sheets:

Sodium Bicarbonate Material Safety Data Sheet | Zinc Orthophosphate Material Safety Data Sheet

Note: Understanding Water pH.

The pH of pure water is 7. In general, water with a pH lower than 7 is considered acidic and with a pH greater than 7, it’s considered basic. The normal range for pH in surface water systems is 6.5 to 8.5 and the pH range for groundwater systems is between 6 to 8.5.